RAIL & METRO

SURVEYS

McDonald Surveys were the first engineering surveying company to introduce the GEDO Vorsys with GEDO Office Suite to Australia for the purposes of Rail Surveying. This came about as a response to our clients’ need for a more efficient, technologically appropriate system. We have proven expertise utilizing this system over many projects.

Our Rail Surveying expertise is broad and can be broken down into the following areas;

- Control Network

A Rail Survey Control Network is a fundamental requirement for any rail system. Accuracy is critical to the ultimate surveying, design, construction and maintenance outcome, and technology advancements allow us to establish control and measure to a degree that has historically been difficult to realise.

- Measurement For Design and Maintenance

We have long standing partnerships with survey technology industry leaders. Being the only WA provider of the Trimble Dual Trolley Gedo Vorsys System we are able to measure the rail assets with greater accuracy and speed, enhancing project delivery with comprehensive data.

Our dual trolley system incorporates Trimble Gedo CE; a suite of tools capable of outputting track measurement data at 0.5 meter intervals, recording cant, gauge and top of rail, ultimately producing highly accurate data sets for Absolute Position of Rail and Relative Track Geometry.

Producing 3D point clouds with defined coordinate information, the Trimble Gedo Scan System is a specific tool we leverage to collect further detailed information about all rail assets and surrounding features within a given operational rail environment.

This technology and our capability supports detailed external design for projects such as; rail realignment, re-sleepering, turnout refurbishment, track renewals and new construction.

- Track & Turnout Build & Renewals

Critical rail sections require ‘right-first-time’ build, maintenance and upgrades, with a need for quick turnaround under high pressure. We have an established record of optimising new construction processes and ensuring completion within shutdown times, during track renewal operations.

We deploy highly skilled expertise to operate our technology, applying captured data to operational processes, which in turn leads to reduced possession times and improved possession forward-planning. Further outcomes include greater compliance, smooth rail alignment and comprehensive management reporting.

We measure rail pre and post tamping operations, with front end measurements (lift, slew and cant) uploaded into the onboard ALC tamper software within minutes.

Through our established processes and the adoption of the GEDO Vorsys technology we are effectively revolutionising the efficiency of the rail renewal and construction process.

- Compliance & Practical Completion

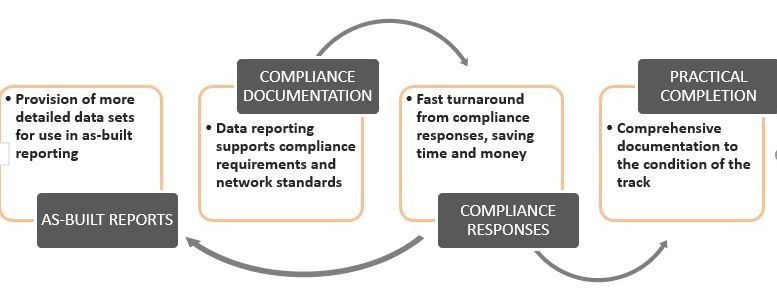

Throughout a project lifecycle, in order to formalise the traceability and performance of each stage and task, we adhere to industry standards relating to compliance, reporting and the practical completion processes. This typically takes the form of four principle stages which are outlined in the diagram below.

We utilise suitable technology reporting to provide prompt and accurate information as required such as;

- Absolute As-Built reports – Lift & Slew, Cant and Gauge Delta’s

- Speed Raiser reports

- Clearance reports – Separation reporting

- Creep and Settlements

- Cross Sections

- DXF & DWG’s

In order to maintain safety and security of such goods and materials, frequent inspection of tracks are essential. Statistics indicate that major derailments happen largely due to human failure or infrequent and inadequate monitoring systems.

Advancement in technology – including that which it utilised by McDonald Surveys – has increased the use of smart monitoring system in railways. This technology has helped achieve cost effective solutions with a higher level of performance which is often times unattainable through human inspection alone.

All staff deployed on projects carry the requisite accreditations for Compliance, Standards and Safety, as governed by the client, primary contractor and/or regulatory body.

This includes:

- Fully accredited rail team – RIW, PTA, Arc Infrastructure, SSSI, Engineers Australia and PMI

- Specialised in-house rail training program

- Project-specific training programmes undertaken, designed to fully comply with client survey specifications

- Collaboration workshops with our industry partners Trimble and Scitech

- All team members St John Remote Location First Aid trained

- Professionally accredited staff

“We deploy highly skilled expertise to operate our technology, applying captured data to operational processes, which in turn leads to reduced possession times and improved possession forward-planning”

WHAT OUR

CLIENTS SAY

GET IN TOUCH

If you have a project you’d like to discuss, please call us on (08) 9353 6140 or complete and submit the form below.

McDonald Surveys International Pty Ltd

1/58 Tarlton Crescent, Perth Airport 6106

T (08) 9353 6140

E enquiries@mcdonaldsurveys.com

© Copyright 2020 McDonald Surveys International Pty Ltd. | Privacy Policy | Terms and Conditions Website design by Crux Creative | Website build by Trapdoor Media